Pharmaceutical Production

|

Handling & Mixing

|

IMA Handling systems include a wide range of ancillary equipment and technical solutions: lifting columns, BINs and drums, tumblers, dispensing and feeding systems and high containment valves. Flexibility is the keyword characterising the IMA handling equipment: the smart solutions offering high performances.

Using the expertise of the IMA engineering department we are able to integrate different equipment of the IMA range into one installation – from single machines to complete Solid Dose facilities.

|

|

The PH-Bin is an IBC (Intermediate Bulk Container) designed to handle and blend powders and granulates. The equipment is manufactured in compliance with the most restrictive GMP requirements and can be interfaced with the loading and unloading systems of the IMA " Pharma Handling Systems ". |

Technical Data

Layout

Details

|

|

|

Cylindrical container - PH-Drum |

|

The PH-Drum is designed for handling powders and granules for the pharmaceutical, food and chemical industry. |

Technical Data

Layout

Details

|

|

|

Lifting columns - Hercules |

|

Hercules lifting columns are designed for handling drums, containers, Intermediate Bulk Containers (IBCs/Bins) and small machines like mills, pneumatic conveyors and calibrators. Hercules Mini 300, Midi and Maxima are available also in the mix version combining lifting and blending. |

Technical Data

Layout

Details

|

|

|

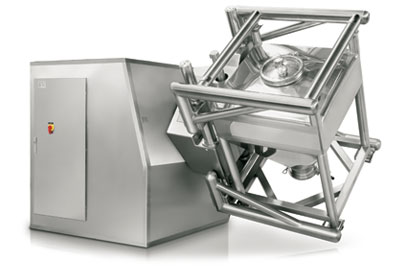

The Cyclops is a very flexible Bin tumbler designed for blending and homogenizing powders and granulates. The machine rotates containers (bins) and is able to generate an efficient mixing effect thanks to the container being tilted by 15° as compared to the rotation axis. |

Technical Data

Layout

Details

|

|

|

Canguro is a Bin tumbler designed for blending and homogenizing powders and granulates. The machine rotates containers (Bins) by means of a standard blocking system. |

Technical Data

Layout

Details

|

|

|

High containment valve - TwinValve |

|

TwinValve is a simple and reliable solution to handle powders, granules, tablets and capsules. It can be used as a standard butterfly valve on bins and can be easily retrofitted on existing Powder Handling Plants allowing containment during powder transfer and high flexibility. |

Technical Data

Layout

Details

|

|

|

Sanitary butterfly valves |

|

The sanitary butterfly valve is designed to handle powders and granules and can be installed on bins or vessels, containers and pipes. |

Technical Data

Layout

Details

|

|

|

The Air Chamber is a patented gravity feeding system with disposable liner to transfer powders, granules, tablets or capsules from an existing bin docking station to a processing or packaging machine in dust-tight conditions. |

Technical Data

Layout

Details

|

|

|

Pneumatic pharma conveyor - VPC |

The pneumatic pharma conveyor VPC is designed for gentle transport of pharmaceutical bulk products and can be used to transfer products directly from/into mixers, reactors, bins, containers, bulk-bags, tablet presses, capsule fillers, filling machines, etc.

- Bulk transportation in an aspirating air stream under vacuum through hoses or pipes, with the use of compressed air only without any electrical parts. It can be used in almost all hazardous and potentially explosive locations with its standard configuration.

-Designed to meet Clean in Place requirements: few accessories are needed to wash/clean and dry it without disassembling in process.

|

.jpg)

Click here to request furher information

|

|

Bag/drum dumping stations for dispensing |

The bag/drum dumping station is designed for powders and granules handling. This unit is ideal for the automation of raw materials used in limited quantities during the production process. The product is directly introduced into pneumatic conveying lines, vacuum or pressure systems or other equipment ensuring a clean and dust-controlled environment while making unloading bagged materials.

- Internal parts in contact with the product are manufactured in AISI 316 stainless steel, mirror polished.

- Large front opening to enable a perfect accessibility during the loading of the bags/little drums and for a better cleaning execution and verification.

|

.jpg)

Click here to request furher information

|

|